The Munters Reventa Lavamatic delivers powerful, reliable air cleaning for modern poultry and pig production, cutting ammonia by over 80% and fine dust by up to 90% through its highly efficient rotating drum-wash system.

Built for heavy-duty, year-round use, the unit keeps emissions low, odours under control and energy consumption minimal, all while requiring very little maintenance.

With modular capacities up to 130,000 m³/h, the Lavamatic offers a dependable, future-proof solution that helps farms meet strict environmental regulations, improve air quality and create a cleaner, safer environment for both animals and workers, consistently delivering strong performance in even the toughest conditions. Over 10 are installed and running in the UK.

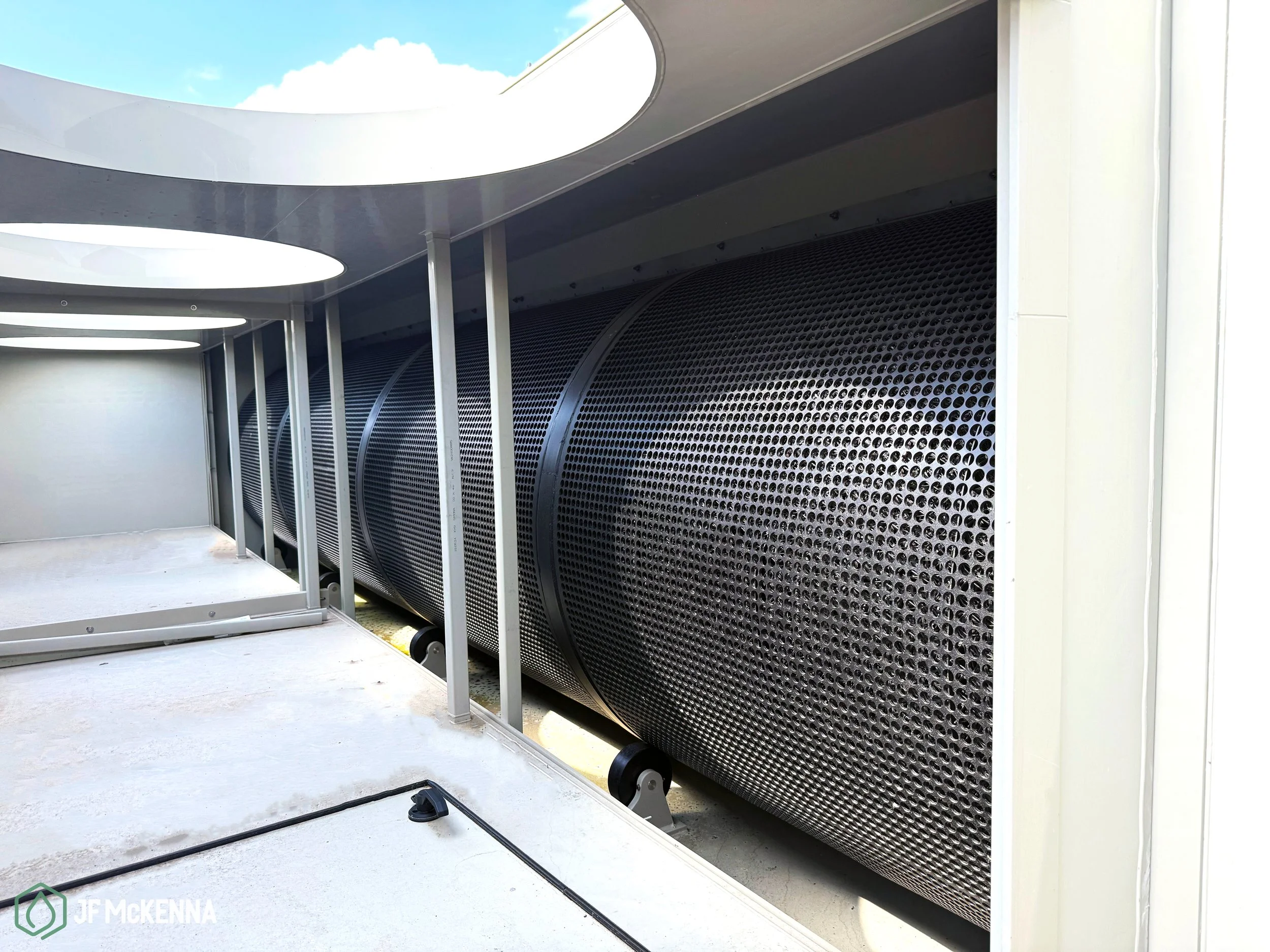

Munters Reventa Lavamatic Air Scrubbers

As air leaves the building through extraction fans, it enters the ‘air scrubber’ where it passes through a water curtain and is washed before being expelled to the outside environment. To maintain good water quality for maximum performance, a connectivity sensor measures the nitrogen in the water and when too high, instructs a valve to send the concentrate to a waste tank. This means the system can continue to run and requires minimal maintenance. The remaining water continues to circulate being heated by the washed air. This heat energy can be later used to condition air for optimal climate back in the building.

These air scrubbers have a large surface area or filter. Air resistance is low, meaning energy consumption of the fans is significantly lower. A unique pumping technique for the rinsing water ensures continuous irrigation of the air scrubber, keeping it completely clean. The pump technology also ensures lower energy costs, because the hydraulic dimensions of the pipe and nozzles mean less water resistance.